Gaspard gustave de coriolis a french scientist developed a new method for measuring the flow of gas or liquids in pipelines based on his principle called the coriolis effect.

Coriolis flow meter working principle animation.

Conversely decelerating fluid moves away from the point of peak amplitude as it exits the tube.

Coriolis flow meters are not available for large pipelines.

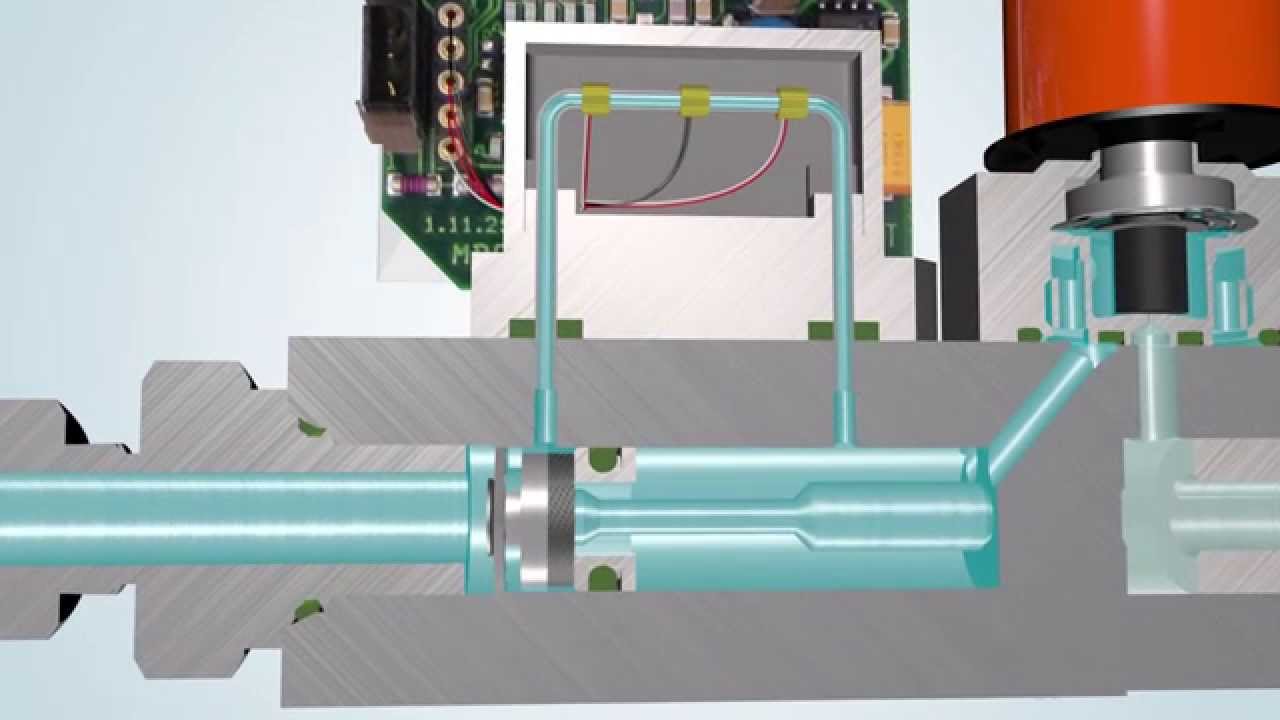

An exciter causes the tube to oscillate.

Fluid is being pumped through the mass flow meter.

The fluid is led through two parallel tubes.

The animation on the right represents how curved tube mass flow meters are designed.

As fluid moves through a vibrating tube it is forced to accelerate as it moves toward the point of peak amplitude vibration.

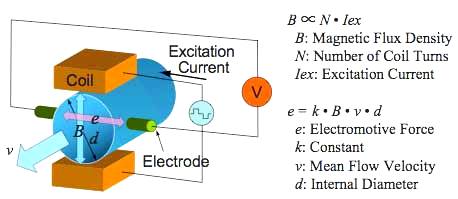

The basic operation of coriolis mass flow meters is based on the principles of motion mechanics.

An actuator not shown induces equal counter vibrations on the sections parallel to the axis to make the measuring device less sensitive to outside vibrations.

The sensor signal is fed into the integrally mounted pc board.

Coriolis flow meter principles the basic operation of coriolis flow meters is based on the principles of motion mechanics.

Coriolis mass flow meter working principle.

A single or dual tube is located inside the pipeline of each coriolis flow meter.

Coriolis mass flow meter contains a vibrating tube in which a fluid flow causes changes in frequency phase shift or amplitude.

When there is mass flow the tube twists slightly.

Disadvantages of coriolis meters.

Coriolis mass flow meter working pricipciple.

The largest coriolis flow meter that is currently available has a maximum flow rating of 25 000 lb min 11 340 kg min and is equipped with 6 in.

.jpg)